EMT16X 2 Million stitch maintenance (Weekly)

Video Demonstration:

Please follow all of the maintenance procedures carefully and apply the proper amounts of the specified lubrication during each step.

Melco cannot be held responsible for any machine damage due to lack of or wrong type of lubrication. Melco cannot be held responsible for any machine damage due to not following the listed maintenance steps.

You will now be guided through the 2,000,000 stitch maintenance procedure covering the following:

– Needle Drive and Upper V-Rail

– Needle Bars

Press the next button to continue.

WARNING!

If you currently have a hoop or clamping system on the machine, please remove it.

Failure to fully remove a clamping system can result in damage to

the machine. When you press on the next button, the machine will move to the

appropriate position.

Needle Drive

Using a small oiler bottle, put twenty-five drops (25) of sewing machine oil in the oiling change as shown in the image.

Note: You may have to add a few drops and wait before adding more to prevent the channel from overflowing. After adding the oil, wait ten minutes before pressing the next button.

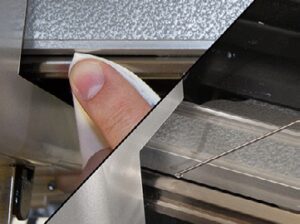

Left Upper V-Rail

Using a piece of lint-free cloth, wipe clean both the front and back surfaces of the upper v-rail on the LEFT side of the needlecase. After cleaning the v-rail, use a small oiler bottle to apply a drop of oil each to the front and the back surfaces of the v-rail. Apply the oil close to the needlecase. When you press the next button, the machine will move to the appropriate position for the next step.

Right Upper V-Rail

Using a piece of lint-free cloth, wipe clean both the front and back surfaces of the upper v-rail on the RIGHT side of the needlecase. After cleaning the v-rail, use a small oiler bottle to apply a drop of oil each to the front and the back surfaces of the v-rail. Apply the oil close to the needlecase.

When you press the next button, the machine will move to the next maintenance position.

Remove needlecase access cover on legacy machines.

Oil Needle Bars (Lower)

Using a small oiler bottle, apply one (1) drop of sewing machine oil to each of the sixteen (16) needle bars through the hole in the needlecase as shown in the image.

Oil Needle Bars (Upper)

Using a small oiler bottle, apply one (1) drop of sewing machine oil to each of the sixteen (16) needle bars by guiding the oiler applicator through the vertical slots of the needlecase cover just below the take up lever arms as shown in the image.

When you press next, the machine will move to the home position.

The following trimmer maintenance steps on legacy machines will vary. Please follow the software steps.

Remove Needle Plate

Using a 2.5mm Allen wrench, loosen and remove the two (2) hex head needle plate screws on either side of the bottom of the lower arm as shown in the image.

Remove the needle plate from the machine.

Remove Link Cover

Remove the link cover by pulling up. It is held in place with two magnets and should release fairly easily.

Clean Link Area

Clean the link area using compressed air. Press the next button to continue.

Replace Link Cover

Replace the link cover with the notched end toward the back of the machine. It is held in place with two magnets.

Oil Trimmer

Place a drop of oil on the upper edge of the movable knife.

Move Knife

Using the 2.5mm Allen wrench as a pin, move the movable knife back and forth ten (10) times to spread the oil. With compressed air, blow out the needle plate.

Using a lint free cloth, wipe the needle plate.

Reinstall Needle Plate

With the movable knife in the back position, place the needle plate back over hook area. Install the two (2) hex head needle plate screws on each side of the bottom of the needle plate as shown in the image. Leave them slightly loose as the needle plate will need to be able to be moved. It will be centred and tightened in a future step.

Lower the Needle

Press the e-stop to free the z-shaft. Reach under the machine and rotate the z-shaft slowly to lower the needle through the hole in the needle plate and to its bottommost position.

Center Needle Plate

Move the needle plate left or right until the needle is centered (left/right) in the needle plate hole as shown in the image. Fully tighten the two (2) hex head needle plate screws.

Release E-Stop

After the needle plate is in place and tightened, release the e-stop by turning the button in the direction of the arrows. When e-stop is released, the machine will move the needle back up to its appropriate position.

Finished!

This completes the 2,000,000 stitch maintenance procedure.

Press the finish button to exit the maintenance procedure.