EMT16X Needle Types

Choosing a Needle

Video Demonstration:

Your machine utilizes DBxK5 needles. Among other things, this means that they are industrial needles with larger eyes.

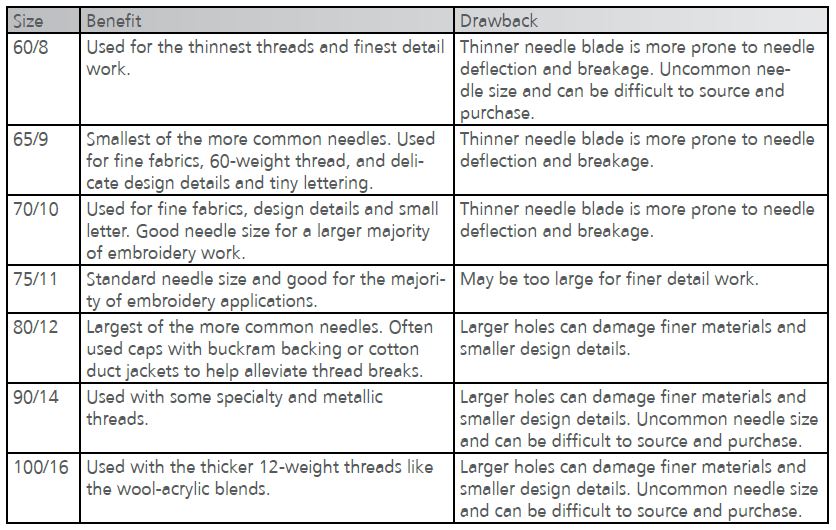

Needle Sizes

Needles come in a variety of sizes, and most are marked with two numbers. For example, you will find 75/11 needles. The first number is metric and is the diameter of the needle blade. It is measured in hundredths of a millimeter.

A 75/11 needle has a blade that is 0.75mm in diameter.

Standard sewing conditions will utilize needle sizes ranging from 65/9 to 80/12 needles.

Smaller needles work well for finer materials, thinner threads, and delicate detail work.

Larger needles work well for tougher and more abrasive materials. As the holes made by the needle are larger, sewing creates less friction on the threads and helps prevent thread breaks.

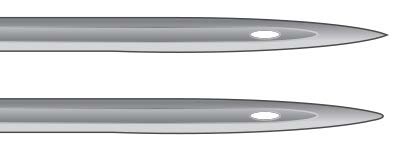

Needle Points

Needle points also come in a variety of options. The main two are sharp and ball point. Sharp point needless are generally better at cutting through materials and are usually used on tightly woven or non-woven.

Ball point needles are most often used on knit materials. They tend to move the threads of the material to the side of the needle as they sew. Ball point needles are usually marked with a “BP” on the package.

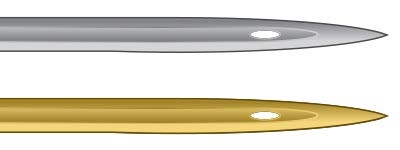

Needle Coatings

Needles are offered with a few different coatings. Standard needles are silver in colour and offer a sewing life of approximately 4 to 6 solid sewing hours.

Other needle coatings exist the cut down on the heat built up when travelling through synthetic materials.