EMT16X Choosing the Right Hoop

Video Demonstration:

Hooping a garment properly and selecting the right hoop for the job is essential to quality embroidery production. The hoop provides the means to move the product at high speeds and accurately place the stitch. If the hoop is too loose, the wrong size, or if the product is hooped poorly, this can adversely affect the design.

NOTE: For the first sew out, the 12cm (4.68 in.) hoop or the 15cm (5.85 in.) round hoop should work well for the 1day.ofm design.

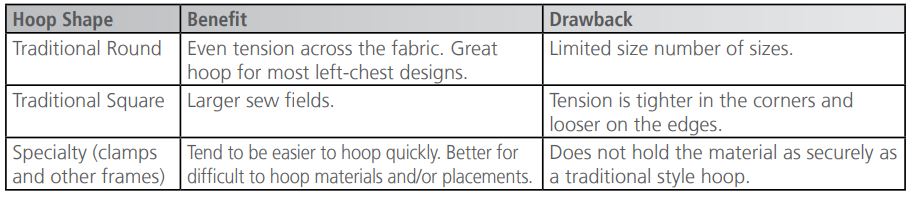

Choosing the Appropriate Hoop Shape

To start, we need to know what type of hoop to use. Each shape has benefits and drawbacks.

Choosing the Appropriate Hoop Size

The ideal hoop for an embroidery design is one that just fits. The design would fall just inside the hoop limits. Why would this matter? It removes the influence of excess material from around the design. This can help with registration (lining up), puckering, and overall stitch quality.

Occasionally there will be obstacles to using the smallest hoop possible for a design. It could be that a button is in the way, or a seam would fall right into the hoop. Adjusting your hoop size to better accommodate the material may be necessary.

Plastic or Wood?

Some of the larger hoops come in either wood or plastic. The wooden hoops are double walled and have more grip than the plastic. However, the inner and outer wooden hoop must remain aligned. The outer hoop cannot be rotated for easier hooping or tightening. Each set of hoops will have a registration number printed on both hoops to help keep them aligned.

Specialty Hoops

Specialty hoops such as clamps and frames that use adhesives are useful when dealing with difficult placements on garments or materials that are hard to hoop.

As they rarely provide the same hold on the materials as a traditional hoop, these hoops tend to be reserved for more specialized applications.