EMT16X Backings & Toppings

Video Demonstration:

Appropriate backing is essential for embroidering most fabrics. Without backing, fabrics can slip even when they are hooped tightly. Using the proper backing is directly linked to the production of consistently high quality embroidery. It is important to understand that many different embroiderers with identical criteria may choose completely different backing and topping formulas and still achieve successful embroidery results. Experimentation and experience are essential in creating consistently high quality embroidery. New products are constantly being developed and introduced. Find the combinations that work best for you.

Backing is placed on the underneath side of a fabric before it is embroidered. It is also sometimes referred to as interfacing or stabilizer. Depending on the material, backing can:

• Stabilize the material as it is being sewn

• Provide support for the stitches after sewing is complete

Different backing types provide varying levels of support.

Cut-away

Cut Away backing is a woven or non-woven material that must be cut form the fabric after the embroidery is complete. This type of backing is used to support the embroidery on the fabric during and after the embroidery process. It also prevents the fabric from stretching during embroidery.

Cut-away backing is a great choice for knits or loosely woven materials. These materials tend to move and stretch. The cut-away backing helps to stabilize the material and support the stitches.

Cut-away backing also has a softer feel to it. If the embroidery is going to eventually be against skin directly, consider using cut-away for a more pleasant experience for the wearer.

As the name implies, cut-away backing must be removed by cutting it away with scissors after the embroidery is complete. It is best to remove leaving ⅛ to ¼ of an inch edge.

Tear-away

Tear away backing is a non-woven material that tears easily in any direction and can be easily removed after embroidery.

Tear away is extremely simple and fast to use, but the uses are limited because it offers little support to unstable fabrics. Some examples of fabrics suitable for tear away are cotton sheeting, heavy woven dress shirts, denim, terry cloth, and hats.

Tear-away backing is a favourite among embroiderers because of it’s ease of removal. It is simply torn away from the garment after the embroidery is finished.

It often has a feel that is similar to paper, and leftovers can be rough against skin.

It is best used with stable materials, as the backing offers little support for the material.

Specialty Backings

Specialty backings such as poly mesh and nylon mesh are also options. While they may not be as stable as traditional cut-aways, they are much less visible through lighter weight garments. They also tend to be softer than other backings.

Water soluble backing is also available for jobs that require that no backing be left after the completion of the embroidery. Be aware that this would require a fairly stable garment as the backing will be dissolved completely and offer no support once the garment has been laundered.

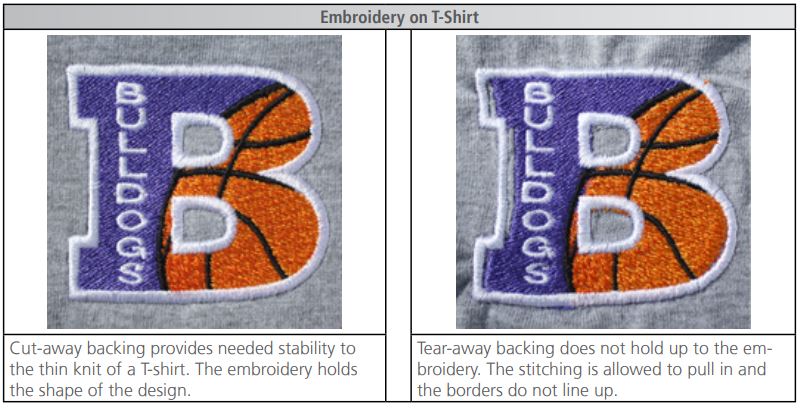

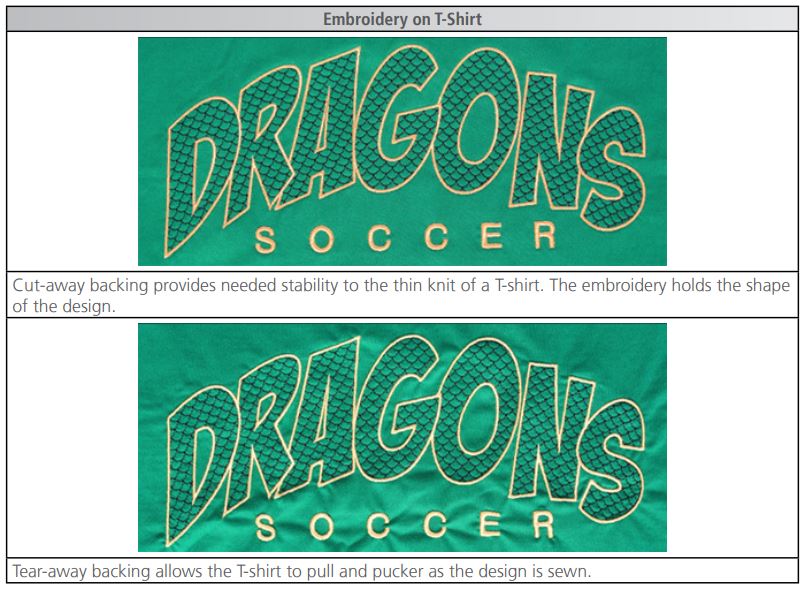

Backing Choice Example

The choice of backing impacts the quality of the embroidery greatly. The following examples were sewn on the same machine with all the same settings. The only difference was the choice of backing.

Backing Weights

Backing comes in different thicknesses. Many times, you can ask for sample packets from suppliers to find what will work best with your application.

Heavier backings tend to offer more support. Lighter backings are often less visible. Because finding the right backing for the application requires some experience or experimentation, having a medium weight backing is a good starting place for new embroiderers.

Toppings

Toppings are used to keep your stitches from falling into the nap of a lofty material like terry cloth or polar fleece. It can also be used to clean up small lettering and the overall appearance of your embroidery. Most toppings are water-soluble and can be easily removed after the embroidery is complete.